WHAT ARE ICF BLOCKS?

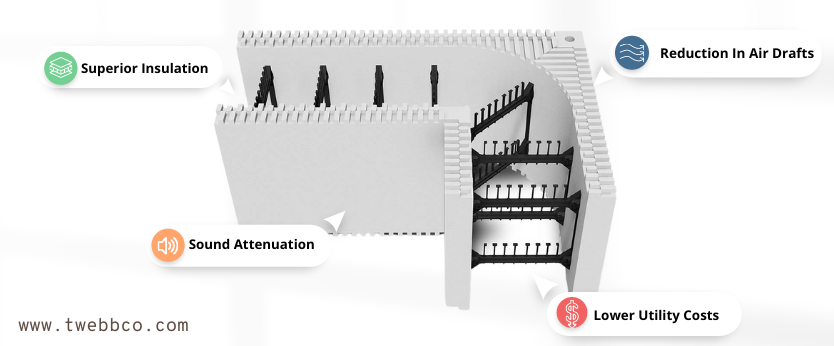

Insulated Concrete Form (ICF) blocks are expanded polystyrene construction materials stacked in the shape of the exterior wall of a building. These blocks are hollow, leaving space where concrete is poured during construction.

Insulated Concrete Forms (ICFs) are becoming the most preferred construction materials by constructors and homeowners. In ICF construction, polystyrene foam blocks with spaces between them are used. These hollow blocks act as the curing medium for firm concrete walls.

This type of construction has tons of benefits for both constructors and homeowners.

How Does It Work?

To form a wall, the ICF blocks are first reinforced with steel bars. Once the ICF blocks are fitted together, concrete is poured to fill the hollow spaces between the blocks. Concrete ensures the walls are air-tight. The ICF blocks have perfect interlocking sections to ensure the wall remains firm.

ICF blocks result in a wall system with unmatched strength, noise reduction, energy efficiency and comfort. These great attributes stem from the brilliant combination of polystyrene blocks, concrete and steel bars. ICF systems vary in size depending on the actual blocks size and insulation levels. ICF wall thickness ranges between 6” and 12” depending on the soil condition. With ICF blocks, you can build your own foundation, resulting in sturdy buildings with high energy efficiency and can be used to make various residential and commercial buildings.

WHAT ARE ICF BLOCKS?

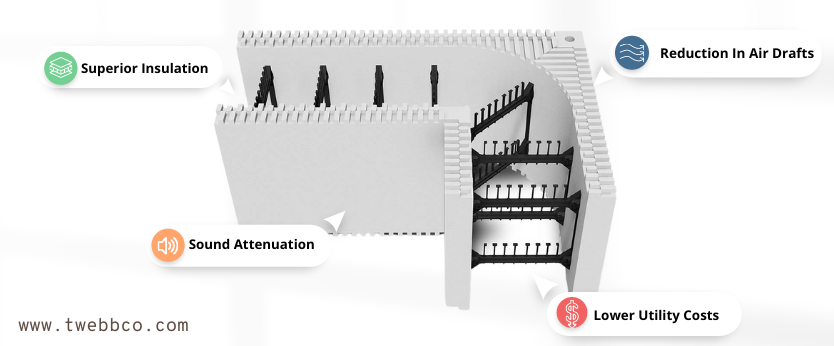

Insulated Concrete Form (ICF) blocks are expanded polystyrene construction materials stacked in the shape of the exterior wall of a building. These blocks are hollow, leaving space where concrete is poured during construction.

Insulated Concrete Forms (ICFs) are becoming the most preferred construction materials by constructors and homeowners. In ICF construction, polystyrene foam blocks with spaces between them are used. These hollow blocks act as the curing medium for firm concrete walls.

This type of construction has tons of benefits for both constructors and homeowners.

How Does It Work?

To form a wall, the ICF blocks are first reinforced with steel bars. Once the ICF blocks are fitted together, concrete is poured to fill the hollow spaces between the blocks. Concrete ensures the walls are air-tight. The ICF blocks have perfect interlocking sections to ensure the wall remains firm.

ICF blocks result in a wall system with unmatched strength, noise reduction, energy efficiency and comfort. These great attributes stem from the brilliant combination of polystyrene blocks, concrete and steel bars. ICF systems vary in size depending on the actual blocks size and insulation levels. ICF wall thickness ranges between 6” and 12” depending on the soil condition. With ICF blocks, you can build your own foundation, resulting in sturdy buildings with high energy efficiency and can be used to make various residential and commercial buildings.

CONTRACTORS, ORDER YOUR ICF BLOCKS TODAY!

CONTACT US

CONTRACTORS, ORDER YOUR ICF BLOCKS TODAY!

CONTACT US

Frequently Asked Questions